How We Do It

Process

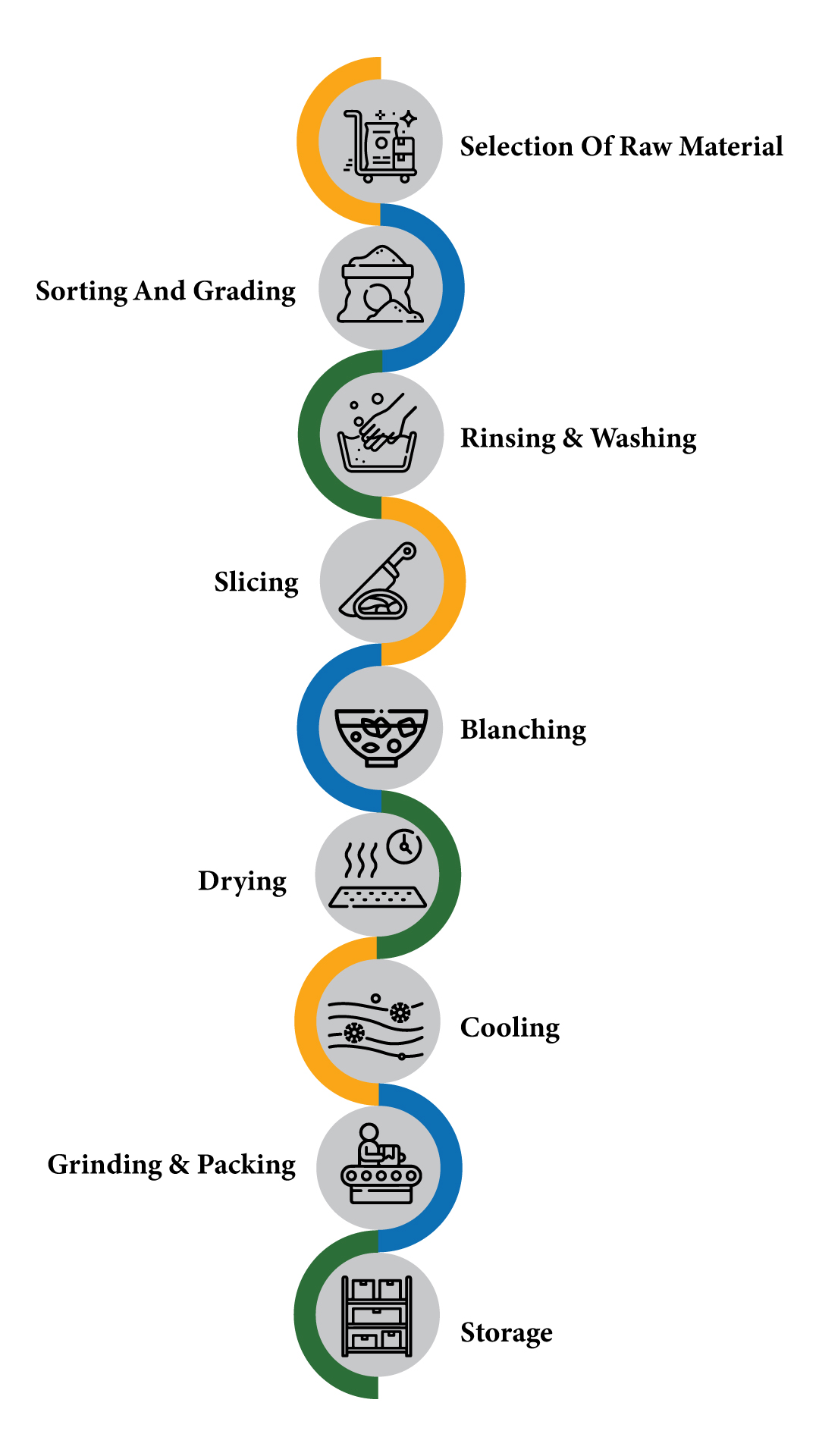

We began with selecting the raw material through proper sensory evaluation, moisture content, Brix concentration, acidity/ pH, and microbial testing to restrict harmful microorganisms that can spoil food.

Then it is sorted and graded, after which we do rinsing and washing with fresh potable water in a bubble washer that leads to the step of washing in which uniform slicing of products are made ranging from 6mm-25mm that goes for blanching to reduce enzymes actions that cause loss of flavor, color, and texture.

After scaling products, multilayer hot air drying is activated under controlled conditions to remove moisture from the food so bacteria, yeast, and mold cannot spoil the food.

To extend the shelf life of fresh and processed food or to maintain a specific temperature then, we go for excellent food slowly and gradually in the cooling chamber; after that, we do grinding to reduce the size of dehydrated products using a grinding machine with specific mesh (i.e., 40-100 mesh size) that is followed by process of airtight sealing by using plastics, epoxy resins glass, etc. to prevent the entry of microorganisms and maintain sterility of contents.

In the end, we do storage in a cool and dry place under a specific temperature of ≤ 30% and ERH ≤ 60%.

Our process ensures high-quality, safe, and healthy dehydrated food for you.